- Home

- >

- Products

- >

- PLC Jacking Systems

- >

- Synchronous Jacking System

Synchronous Jacking System

Brand :jkyeya

Product origin :China ShanDong

Delivery time :3 days

Supply capacity :100

China Synchronized Lifting Jacks, Hydraulic Hose Press Customized

System Features:

1. High-speed zero setting and smooth lifting function with dual pump system

2. Full computer control, the jacking process does not require manual intervention, Hydraulic Hose Press Customized the system automatically detects the jacking state and can be given according to the jacking situation;

3. Synchronous control accuracy can be achieved. Synchronous jacking and synchronous descent are fully controllable;

4. The oil path of each control point is relatively independent, and the system pressure can be adjusted independently without interference.

5. The main components of the system are all well-known international brands, China Synchronized Lifting Jacks and the seals are all imported and sealed;

6. Applicability is more extensive, can be used with single-acting jack or double-acting jack

7. Hydraulic Hose Press Customized The system is easy to use, and the hydraulic pipeline is connected with the hydraulic jack and the hydraulic pump unit.

8. Equipped with high-precision displacement sensor and pressure sensor for real-time monitoring and feedback of system conditions

working principle:

1. The pulse width synchronous control system is a hydraulic jacking system, industrial computer PLC control technology, displacement monitoring and bridge structure analysis and construction technology.

2. Integrate and develop a complete set of technologies on an integrated system.

3. The core technology hydraulic pump station uses the on-off valve to control the flow, China Synchronized Lifting Jacks and adjusts the switching frequency of the on-off valve to change the flow rate to achieve the oil pump.

4. The output flow can be adjusted with the purpose of computer control system and detection feedback system to form pressure and displacement closed-loop control, which can be precisely controlled.

5. Hydraulic Hose Press Customized Each jack is load balanced during synchronization and weighing during lifting.

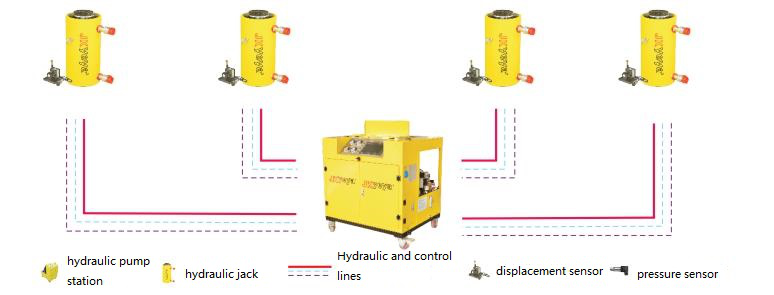

System connection diagram:

Specfication:

Synchronization points | Model | Rating pressure | Rating flow | Oil tank capacity | Power parameter | Oil cylinder | Shape size |

Mpa | L/min | L | (380v,50Hz) | single/double | mm | ||

2 | MSC0*3-02 | 70 | 0.75 | 40 | 1.1Kw | both | 800*760*900 |

4 | MSC0*3-04 | 70 | 1.13 | 100 | 1.5Kw | both | 800*760*900 |

8 | MSC0*3-08 | 70 | 2*1.13 | 2*100 | 2*1.5kw | both | 2*800*760*900 |

16 | MSC0*3-16 | 70 | 4*1.13 | 4*100 | 4*1.5kw | both | 2*800*760*900 |

24 | MSC0*3-24 | 70 | 6*1.13 | 6*100 | 6*1.5kw | both | 2*800*760*900 |

32 | MSC0*3-32 | 70 | 8*1.13 | 8*100 | 8*1.5kw | both | 2*800*760*900 |

48 | MSC0*3-48 | 70 | 12*1.13 | 12*100 | 12*1.5kw | both | 2*800*760*900 |

64 | MSC0*3-64 | 70 | 16*1.13 | 16*100 | 16*1.5kw | both | 2*800*760*900 |

Operation steps:

1. Ensure the correct use of the hydraulic jack. The correct use of the jack can refer to the precautions for the use of the jack and correctly install the displacement sensor.

2. Hydraulic Hose Press Customized Connect the hydraulic line and sensor line and connect the power cord

3. After installing the pipeline, check the pipeline and sensor line in manual mode after power on.

4. Before the synchronous jacking operation, first change the mode to the manual ascending mode, and then execute the closing button, China Synchronized Lifting Jacks the jack starts to rise, when the actual pressure reaches.When the pressure value is reached, the jack automatically stops lifting. The setting value of the closing pressure is: the optimum setting value is about 30% of the actual load.

5. After the fitting is completed, set the target displacement amount first. When the up button is pressed, China Synchronized Lifting Jacks the jack will automatically rise and rise to the set target value Stop the action automatically.